Congratulations! Your project works! You’ve dedicated a bunch of research, time, and resources to getting it to perform the fun or vital function. Now to make it pretty, more reliable, or to make a lot of them you need to recreate your circuit on a PCB (printed circuit board).

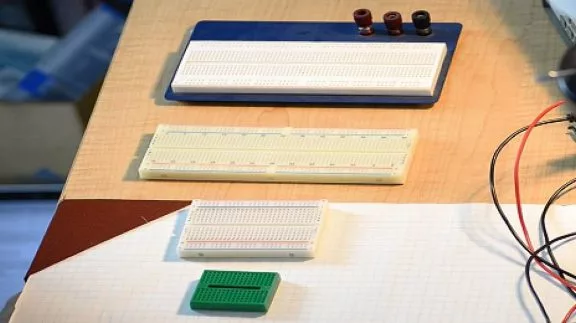

An intermediate step, or even an option to PCB and the design time/cost of PCBs - is to use veroboard or solderable breadboard. This would be flatter/thinner than a breadboard, and components are more secure than on a breadboard.

You’ll need a PCB design tool

For dipping your toes into PCB design you can use free or trial versions of many of the standard design suites like Altium, Eagle, and Autodesk.

There are also many free tools out there like Fritzing, EasyEDA, and KiCad to try without as much commitment. This is only a very small sample of what is available, and all the features that are included (or not) with these tools would make for a set of articles on their own. One place to check are the many different PCB production services available. Their websites and design requirements always give file requirements and sometimes recommendations for design programs to use.

You’ll need a way to produce it

1. Home etching - You can go through a traditional etching process similar to how large scale PCB production used to be is done. The design is optically transferred to a copper sheet and then the unwanted copper is etched away. With the other methods available, this is not favored anymore.

2. Routing - With greater access to CNC machines, routing the PCB in small batches has become more popular. This has an advantages over chemical processes, with speed and no chemicals to worry about. These are nice in that the design should be reproduced accurately and revisions are easy to make. After you have a working design, it can be in your hands as fast as it can be routed.

3. PCB services - The best results, with final PCBs that are professionally produced with industry standard processes comes from the many new PCB fabrication houses geared towards makers, hobbyists, and prototypes. With proper design on your part, your boards could be indistinguishable from commercially produced boards. The downsides are the turnaround times, cost, and commitment you make when sending your design out.

Once you send the design to be produced, you are committed, so double check it and if you can have someone else familiar with your project and PCB design considerations check it too. Tools often have DRC checks built into them, however they don’t know the function of your circuit, only that rules must be followed like traces cannot be too close together, cross, or that all the connections in your schematic are made in the PCB.

Once your PCB is made, all you have to do is populate it like your breadboard, but with all the added benefits that a printed circuit board offers. Good Luck!