Thermoelectric cooling relies on electricity for cooling and operates according to the Peltier effect. Peltier effect is the cooling of one junction and the heating of the other when electric current is maintained in a circuit of two conductors. The effect creates a temperature difference by transferring heat between two electrical junctions and is even stronger in circuits with dissimilar semiconductors.

This effect was discovered in 1834 by the French physicist Jean-Charles-Athanase Peltier. In a circuit consisting of a battery joined by two pieces of copper wire to a length of bismuth wire, a temperature rise occurs at the junction where the current passes from copper to bismuth, and a temperature drop occurs at the junction where the current passes from bismuth to copper. Basically, when the current flows through the junctions of the two conductors, heat is removed at one junction and cooling occurs while heat is deposited at the other junction. The main application of the Peltier effect is cooling. However the Peltier effect can also be used for heating or temperature control. In every case, a DC voltage is required.

Thermoelectric cooling (TEC) or Peltier cooling is also known as solid-state cooling, because there is no liquid refrigerant running through the machine. Instead, solid metal is used to transfer thermal energy.

Structure

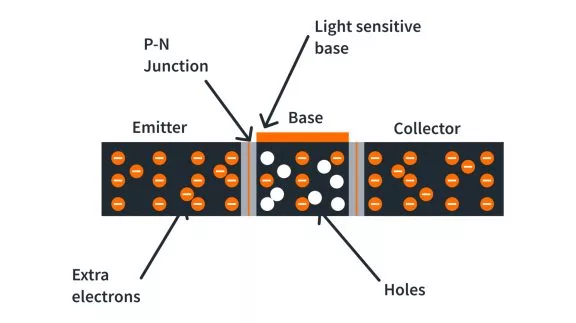

It is essential to have a difference in electron densities, hence two unique semiconductors (one n-type and one p-type) are used. The alternating p & n-type semiconductor pillars are placed thermally in parallel to each other and electrically in series and then joined with a thermally conducting plate on each side (usually ceramic), avoiding the need for a separate insulator.

When a voltage is applied there is a flow of DC current across the junction of the semiconductors, causing a temperature difference. The cold side cools an object or material to the desired temperature, while the hot side is connected to a heat sink, where metal fins help dissipate excess heat on the outside of the appliance. The side with the cooling plate absorbs heat which is then transported by the semiconductor to the other side of the device. The cooling ability of the total unit is proportional to the total cross section of all the pillars, which are often connected in series electrically to reduce the current needed. Different types of thermoelectric coolers include single-stage and multi-stage (see CUI Devices).

Advantages and Disadvantages

In general, Peltier coolers work best in small spaces, particularly for electronic devices where there isn't enough space for a compressor-based cooler. Some advantageous features include:

No Moving Parts: TE coolers work electrically without any moving parts so they are virtually maintenance free.

Small Size and Weight: The overall thermoelectric cooling system is much smaller and lighter than a comparable mechanical system. In addition, a variety of standard and special sizes and configurations are available to meet strict application requirements.

Ability to Cool Below Ambient: Unlike a conventional heat sink whose temperature necessarily must rise above ambient, a TE cooler attached to that same heat sink has the ability to reduce the temperature below the ambient value.

Ability to Heat and Cool: Thermoelectric coolers will either heat or cool depending upon the polarity of the applied DC power. This eliminates the necessity of providing separate heating and cooling functions within a given system.

Precise Temperature Control: With an appropriate closed-loop temperature control circuit, TE coolers can control temperatures to better than +/- 0.1°C.

Orientation Flexibility: TE coolers can be used in any orientation and in zero gravity environments. Thus they are useful in many aerospace applications.

Spot Cooling: With a TE cooler it is possible to cool one specific component or area only, useful when it is unnecessary to cool an entire package or enclosure.

Environmentally Friendly: Conventional refrigeration systems cannot be fabricated without chlorofluorocarbons or other chemicals that may be harmful to the environment. Thermoelectric devices do not use or generate gas of any kind.

An issue with performance is a direct consequence of one of the advantages: being small. This means that the hot side and the cool side will be very close to each other (a few millimeters away), making it easier for the heat to go back to the cool side, and harder to insulate both sides from each other. TEC systems have other notable disadvantages. Foremost is their limited energy efficiency compared to conventional vapor-compression systems and the constraints on the total heat flow that they are able to generate per unit area. Thermoelectric cooling units quickly become costly when used in large spaces. This is because more ceramic material is used to cover a larger area, and this will require higher input voltage to operate, whereas a slightly larger compressor doesn't use that much more electricity than a smaller one. Due to this lower efficiency, thermoelectric cooling is generally only used in environments where the solid-state nature (no moving parts), low maintenance, compact size, and orientation insensitivity outweighs pure efficiency.